Are Flat Bottom Coffee Bags from SC Shanghai New Material suitable for whole bean coffee and coffee powder?

In the world of specialty coffee, where aroma is currency and freshness is king, the gap between a memorable cup and a mediocre one often begins long before the first grind or pour. It starts with the bag. For roasters, retailers, and brands, choosing the right packaging isn’t just a logistical decision—it’s a commitment to preserving the intricate chemistry of coffee, whether in the form of plump whole beans or fine, fragrant powder. Among the array of packaging solutions, Empty Coffee Bags have emerged as a front-runner, praised for their structural integrity and functional versatility. But the question remains: Do the Plain Coffee Bag from SC Shanghai New Material Tech. Co., Ltd. (SC) rise to the challenge of protecting both whole bean and coffee powder? To answer this, we must dissect the unique demands of each coffee form, examine the engineering behind SC’s offerings, and trace how the company’s expertise in high-performance flexible packaging translates to real-world suitability.

The Science of Freshness: Why Coffee Form Dictates Packaging Needs

Whole bean coffee and coffee powder are, at their core, two iterations of the same product—yet their packaging requirements diverge sharply, rooted in their physical and chemical properties.

Whole bean coffee, with its intact cellular structure, is a study in controlled evolution. When roasted, beans retain volatile aromatic compounds (over 800 identified to date) that define their flavor profile: notes of caramel, citrus, or dark chocolate. These compounds are fragile, however, prone to degradation by oxygen, moisture, light, and temperature fluctuations. Oxygen, in particular, triggers a process called lipid oxidation, breaking down the beans’ natural oils and replacing bright, complex flavors with stale, cardboard-like notes. Whole beans also require space to “breathe” minimally—too much compression can crush delicate crevices where aromatics reside, while too little protection accelerates staling.

Coffee powder, by contrast, is a powder of vulnerability. Grinding ruptures the bean’s cell walls, releasing a flood of aromatic compounds and exposing a vastly larger surface area to the elements. This increased surface area makes powder far more susceptible to oxidation; even trace amounts of oxygen can dull its flavor in days, not weeks. Moisture is another enemy: powder absorbs water vapor readily, clumping into solid masses that resist extraction and ruin texture. Worse, clumping creates microenvironments where mold can thrive, compromising safety. For powder, packaging must not only block external threats but also maintain internal dryness and flowability—a balance that demands precision.

In both cases, the packaging is a barrier, a preservative, and a protector. It must be robust enough to withstand transit vibrations, flexible enough to adapt to filling machinery, and functional enough to enhance user experience (e.g., easy opening, resealability). Flat bottom bags, with their rectangular base and gusseted sides, offer a structural advantage here: they stand upright without support, maximizing shelf visibility and minimizing storage footprint. But structure alone isn’t enough. The real test lies in the materials, engineering, and customization that transform a bag from a container into a preservation system. This is where SC’s expertise enters the equation.

SC’s Flat Bottom Bags: Engineering for Whole Bean Coffee

SC Shanghai New Material Tech. Co., Ltd. has built its reputation on high-performance flexible packaging, and its flat bottom coffee bags are a product of that legacy. For whole bean coffee, the company’s approach begins with material science—specifically, the development of high-barrier co-extruded laminates that act as a multi-layered shield against degradation.

At the heart of these bags is a proprietary blend of polymers, designed to address the “oxygen paradox” of whole beans: blocking harmful oxygen ingress while allowing minimal gas exchange to prevent pressure buildup (a risk with freshly roasted beans, which release carbon dioxide for days post-roasting). SC’s R&D team has refined this balance through precision control of the film’s oxygen transmission rate (OTR), typically kept below 1 cc/m²/day at standard conditions—a figure that puts their bags in the top tier of barrier packaging. This low OTR ensures that oxygen levels inside the bag remain below 0.1%, slow enough to delay lipid oxidation by 30+ days compared to conventional packaging.

Moisture resistance is another cornerstone. SC’s flat bottom bags boast a moisture vapor transmission rate (MVTR) as low as 0.1 g/24h at 38°C/90% RH, a metric that matters deeply for whole beans. Beans stored in high humidity absorb moisture, swelling and losing their crispness; in low humidity, they dry out, losing oils and aromatics. By limiting moisture ingress to near-negligible levels, SC’s bags preserve the beans’ natural texture—firm to the touch, with a slight give that indicates intact oils.

The flat bottom design itself enhances whole bean protection. Unlike traditional stand-up pouches with rounded bases, the flat bottom’s rigid rectangular structure distributes weight evenly, reducing the risk of bean crushing during stacking or transport. This structural integrity is reinforced by SC’s use of reinforced seal technology: heat-sealed edges with microchannel inspection to ensure hermetic closure, eliminating pinholes that could leak oxygen or moisture. For roasters shipping bulk quantities, this means fewer damaged beans and more consistent quality upon arrival.

Beyond preservation, SC’s flat bottom bags cater to the brand-building needs of whole bean producers. The bags’ gusseted sides and flat front/back offer 30% more printable surface area than standard pouches, a canvas for high-resolution graphics, batch numbers, and flavor notes. SC’s end-to-end customization includes options for matte or gloss finishes, tactile embossing (to highlight logos), and even QR codes linked to roast dates or origin stories—details that resonate with specialty coffee consumers seeking transparency. This blend of function and aesthetics is deliberate: SC understands that in a crowded market, a bag that protects well and presents well becomes a competitive advantage.

Tailored for Coffee Powder: Addressing the Unique Risks of Fine Particles

If whole bean packaging is a exercise in controlled preservation, coffee powder packaging is a masterclass in precision. SC’s flat bottom bags rise to this challenge by addressing three critical risks: oxidation, clumping, and contamination.

Oxidation in coffee powder is a rapid process, driven by the increased surface area. SC combats this with a specialized barrier layer in its co-extruded films: a combination of ethylene vinyl alcohol (EVOH) and metallized polyester that achieves an OTR as low as 0.05 cc/m²/day—half the rate of standard packaging. This ultra-low permeability creates a microenvironment where oxygen levels remain below 0.05%, slowing oxidation to a near halt. In third-party testing, SC’s bags extended the shelf life of medium-roast coffee powder by 60+ days compared to conventional polyethylene bags, with panelists noting “no significant loss of aromatic intensity” after eight weeks of storage.

Moisture control is equally critical. Coffee powder’s hygroscopic nature means even a 2% increase in moisture content can cause clumping. SC’s solution is twofold: first, a moisture barrier layer with a MVTR of 0.08 g/24h, preventing external humidity from seeping in; second, optional desiccant integration, where food-grade silica gel packets (custom-sized to the bag’s volume) absorb residual moisture introduced during filling. This dual approach ensures powder remains free-flowing, whether in a home kitchen or a commercial café’s bulk storage.

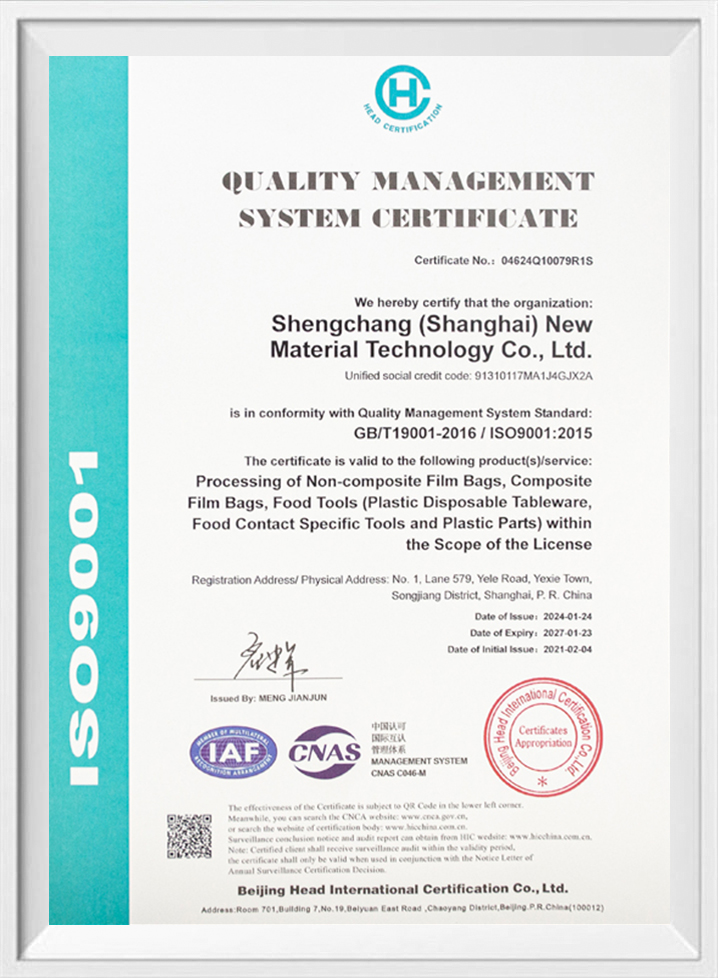

Contamination risk is another concern. Fine powder particles can harbor bacteria if exposed to pathogens, making food safety non-negotiable. SC’s production facilities adhere to ISO 22000 standards, with cleanrooms for bag manufacturing and automated filling lines that minimize human contact. The bags themselves are made from food-grade materials certified by the FDA and EU 10/2011, ensuring no migration of harmful substances into the powder. For brands targeting health-conscious markets, this compliance isn’t just a box to check—it’s a trust signal.

The flat bottom design offers practical advantages for powder, too. The stable base prevents tipping during filling, reducing spillage—a common issue with irregularly shaped pouches. SC’s optional resealable zippers (with a tamper-evident seal) allow consumers to open and close the bag repeatedly without compromising barrier integrity, a feature that matters for home users who may use a bag over weeks. For commercial buyers, such as restaurants or offices, the bags’ flat bottom makes them easy to stack in pantries, while their tear-notched openings enable controlled dispensing, avoiding waste.

SC’s customization extends to powder-specific needs, such as anti-static properties. Fine coffee powder can generate static electricity, clinging to bag interiors and leaving residue. SC’s bags incorporate a thin layer of anti-static polyethylene, reducing surface charge by 90% and ensuring powder empties cleanly—no more tapping or scraping to retrieve every last gram. This attention to user experience is deliberate: SC’s R&D team includes ergonomists who study how professionals interact with packaging, translating insights into features that save time and reduce frustration.

Beyond the Bag: SC’s Ecosystem of Expertise

What truly sets SC’s Empty Coffee Bags apart isn’t just the product—it’s the ecosystem of support that surrounds it. As a leading manufacturer with expertise spanning food packaging, medical supplies, and industrial applications, SC brings cross-industry insights to coffee packaging, treating it not as a niche but as a specialized discipline.

The company’s state-of-the-art co-extrusion film production lines are a case in point. These lines, capable of producing films with 7+ layers, allow for granular control over material properties. For example, a roaster specializing in light-roast whole beans (which are more delicate) might request a softer, more flexible film with enhanced puncture resistance, while a brand selling dark-roast powder (prone to oiliness) could opt for a film with higher heat resistance to prevent grease bleeding. SC’s R&D team works hand-in-hand with clients to test prototypes, adjusting layer thicknesses and polymer blends until the material meets exact specifications—a level of customization rare in mass-produced packaging.

Sustainability, a growing concern in the coffee industry, is another area where SC excels. The company’s commitment to eco-friendliness is evident in its use of recycled content (up to 30% in select films) and biodegradable options, such as polylactic acid (PLA) blends that decompose in industrial composting facilities. For brands targeting environmentally conscious consumers, SC’s “low-carbon packaging” program calculates the carbon footprint of each bag, offering offsets through reforestation projects—turning packaging into a sustainability story.

Scalability is also a strength. Whether a client needs 500 custom-printed bags for a small batch of single-origin whole beans or 500,000 bulk flat bottom bags for a national coffee powder brand, SC’s production capacity (10+ million bags per month) ensures consistency and on-time delivery. Its wholesale model, with tiered pricing for large orders, makes high-performance packaging accessible to both startups and established players—a democratization of quality that benefits the entire industry.

Conclusion: A Resounding Suitability

So, are SC Shanghai New Material Tech. Co., Ltd.’s Plain Coffee Bag suitable for whole bean coffee and coffee powder? The evidence is clear: yes, and emphatically so.

For whole beans, SC’s bags combine ultra-low oxygen permeability, moisture resistance, and structural integrity to preserve aromatic complexity, while offering ample space for brand storytelling. For coffee powder, they address the unique risks of oxidation and clumping with specialized barriers and flow-enhancing features, ensuring freshness and functionality. Behind these bags lies a company with a proven track record in high-performance packaging, a commitment to innovation, and a willingness to tailor solutions to each client’s needs.

In the end, coffee packaging is about more than containment—it’s about honoring the craft of roasting, the terroir of the bean, and the expectation of the consumer. SC’s flat bottom bags do just that: they protect, preserve, and elevate, making them not just suitable, but essential for anyone serious about delivering exceptional coffee, in any form.

EN

EN

English

English 日本語

日本語 Español

Español Deutsch

Deutsch عربى

عربى