Frozen food packaging bags are designed to protect food from moisture, oxygen, odors, and freezer burn, while maintaining the quality and safety of the product during storage and transport. The choice of material plays a critical role in determining how well the bag performs under freezing conditions. The most commonly used materials include:

Content

1. Low-Density Polyethylene (LDPE)

Properties:

LDPE is a lightweight, flexible, and transparent plastic that can withstand freezing temperatures without cracking or breaking. Its natural softness allows the bag to conform to the shape of the food, making it suitable for a wide range of frozen items.

Advantages:

- Provides a good moisture barrier to prevent ice crystals from forming on the food surface.

- Resistant to punctures and tears for standard frozen food storage.

- Easy to seal with heat, twist ties, or zip-lock mechanisms.

Common Applications:

LDPE is commonly used for packaging frozen fruits, vegetables, baked goods, and pre-portioned meals. Its flexibility makes it ideal for irregularly shaped items and household freezer use.

2. High-Density Polyethylene (HDPE)

Properties:

HDPE is stronger and more rigid than LDPE, offering enhanced durability and resistance to punctures. It maintains integrity at low temperatures, making it ideal for heavier or sharper food items.

Advantages:

- Excellent strength protects against accidental tears and punctures during handling and stacking.

- Lightweight yet durable, reducing shipping and storage costs.

- Provides a reliable barrier against moisture and contaminants.

Common Applications:

HDPE bags are often used for meats, seafood, cheese blocks, and bulk frozen foods that require additional protection against rough handling.

3. Polypropylene (PP)

Properties:

PP is a transparent, heat-resistant plastic with a higher melting point than LDPE or HDPE. This makes it suitable not only for freezing but also for reheating or cooking processes like boiling or sous-vide.

Advantages:

- Maintains structural integrity during freezing, heating, or microwaving.

- Resistant to moisture, chemicals, and odors.

- Offers a clear surface, allowing easy visibility of the contents.

Common Applications:

PP bags are ideal for vacuum-sealed frozen meals, ready-to-cook foods, and products that may need reheating directly in the packaging.

4. Nylon (Polyamide, PA)

Properties:

Nylon is a strong, puncture-resistant material that provides excellent barrier properties against oxygen and moisture. This helps preserve the quality, texture, and flavor of frozen food over extended storage periods.

Advantages:

- Prevents freezer burn and slows oxidation, maintaining freshness.

- Very durable, able to withstand rough handling during transport.

- Compatible with vacuum sealing to extend shelf life.

Common Applications:

Nylon is widely used for vacuum-sealed meats, seafood, and premium frozen products that require long-term storage and superior protection.

5. Multi-Layer Laminates

Composition:

Multi-layer laminated bags combine two or more materials, such as LDPE, PP, nylon, or even aluminum foil, to provide maximum protection.

Advantages:

- Offers superior barrier properties against moisture, oxygen, odors, and light.

- Prevents freezer burn and helps maintain food quality for longer periods.

- Can include decorative or printed layers for branding and labeling.

Common Applications:

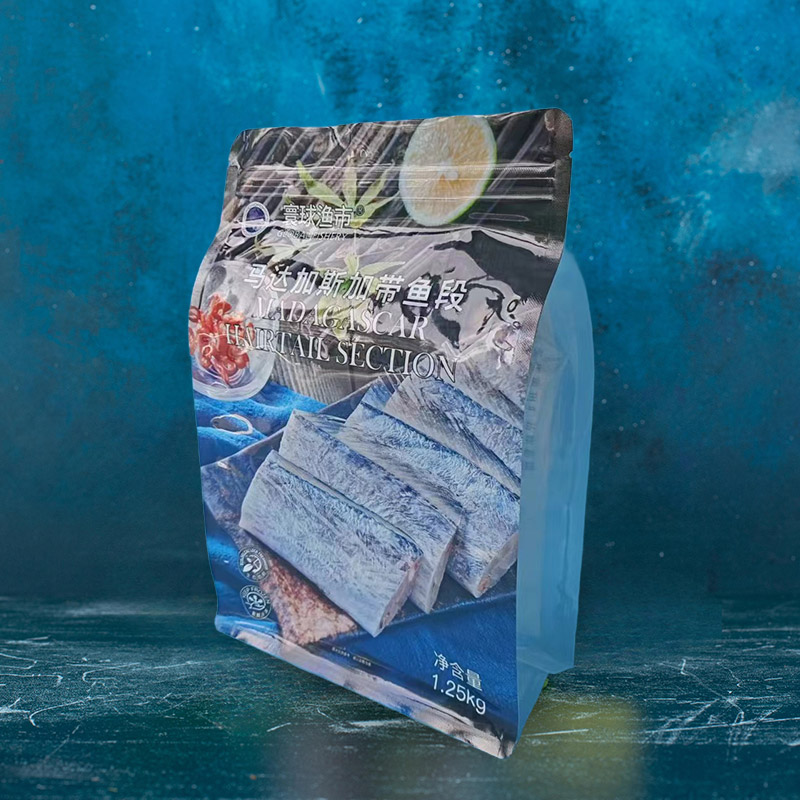

Multi-layer laminates are used for high-value frozen foods, such as seafood, specialty meats, gourmet meals, and products intended for commercial sale or export.

Additional Considerations

When choosing a material for frozen food packaging bags, consider the following factors:

- Food Type: Wet foods like fish or soups may require thicker, more durable materials like HDPE or multi-layer laminates, while dry items may be stored in LDPE.

- Storage Duration: Short-term household freezing may only require LDPE, while long-term or commercial storage benefits from nylon or multi-layer bags.

- Freezer Conditions: Extreme cold or fluctuating temperatures may require stronger, puncture-resistant materials to avoid cracking.

- Reheating Needs: Foods that may be reheated directly in the bag require heat-resistant materials such as PP.

Summary

- LDPE: Flexible, moisture-resistant, ideal for everyday frozen foods.

- HDPE: Strong, puncture-resistant, suitable for heavy or sharp-edged items.

- PP: Heat-resistant, perfect for vacuum-sealed and reheatable foods.

- Nylon (PA): Oxygen barrier, prevents freezer burn, best for long-term storage.

- Multi-Layer Laminates: Maximum protection against moisture, air, and odors, suitable for high-value or sensitive products.

Selecting the appropriate material ensures that frozen food remains safe, fresh, and high-quality, while minimizing waste and maintaining the product’s appearance and flavor.

EN

EN

English

English 日本語

日本語 Español

Español Deutsch

Deutsch عربى

عربى